2022 - 2025 (Part Time)

Auckland, New Zealand

Case Study: Fiery Creations - Full Business Transformation

The Challenge: Reviving and Relocating a Mothballed Business

In 2021, I purchased the assets of a 15-year-old artisan glass slumping business that had closed due to COVID-19. The acquisition included equipment only, which I relocated from Whangarei to North Shore, Auckland, and a 3-month training allowance from the previous owners.

Within two days of training, I had mastered their entire production process, identified significant operational improvements, and brainstormed expansion ideas. I did not need to contact the previous owners for assistance again.

The most critical issue was a major Health & Safety risk: the production process involved sprinkling lead-based glass powders onto glass sheets through laser-cut templates. This created a hazardous environment filled with airborne silica (glass) and lead particles. The powder was also easily disturbed, which could ruin the products and require starting over.

The piece of glass with its powder design was then placed onto a ceramic mold. These were then put into an electric kiln and fired to over 800°C, where the powdered glass design would melt into the base glass, and both would slump into the shape of the mold they were on.

The Solution: Total Process Re-engineering & Vertical Integration

My strategy was to completely re-engineer the business from the ground up, prioritising safety, efficiency, and market expansion.

Safety & Process Innovation: I immediately ceased use of the lead-based powders and scoured the globe for a lead-free alternative. I then purchased the assets of a screen-printing business, developed a new medium to turn the lead-free glass frit into a printable ink, and built a new production process around screen printing the designs onto the glass. This completely eliminated the H&S hazard and created a more consistent, scalable product.

Efficiency & Optimisation: The new process, combined with extensive R&D, allowed for a total overhaul of production efficiency.

Kiln Time: I refined the kiln firing schedule, cutting it from 13 hours to 11 hours and enabling two full firings per day (previously one).

Labour: I reduced glass production and kiln loading time from 16 person-hours (2 workers x 8 hours) to 4 person-hours (1 worker x 4 hours).

Process: I also eliminated the need for a second firing on any product, streamlining the entire workflow and saving an additional 13 hours on some products.

Brand & Product Expansion: I used the new capabilities to expand the entire product ecosystem.

Redesign: Re-designed the existing products (bowls, plates, dishes) for the new printing method and added over 100 new designs.

New Categories: Sourced new materials (local timber veneer MDF) and used the existing laser cutter to design and launch a new range of laser-cut wall art and redesigned product display stands.

Packaging Innovation: Designed stylized, protective display packaging for every product, which included a complimentary display stand and marketing flier. This eliminated breakages, optimised products for perfect stacking in shipping outers, and significantly increased the perceived retail value.

In-house Services: Leveraged the in-house print and design business to create our own decals, support client work, and assist other businesses with product prototyping.

Key Achievements & Impact

Full-Stack Business Management: As the sole operator, I personally managed the entire business move and fitout, accounts, B2B/B2C marketing, R&D, product photography, and all local/international raw material sourcing.

E-commerce & Digital Marketing:

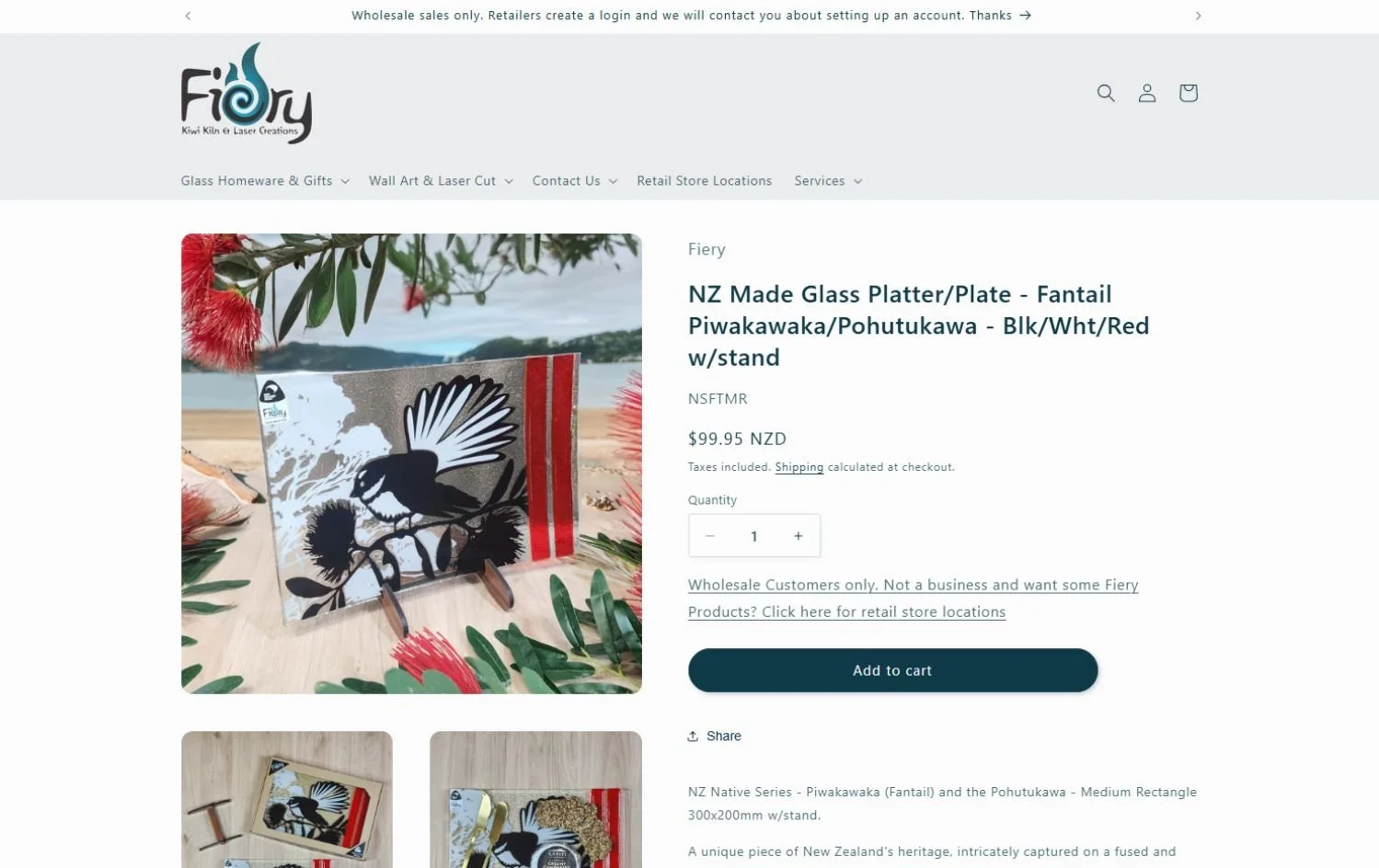

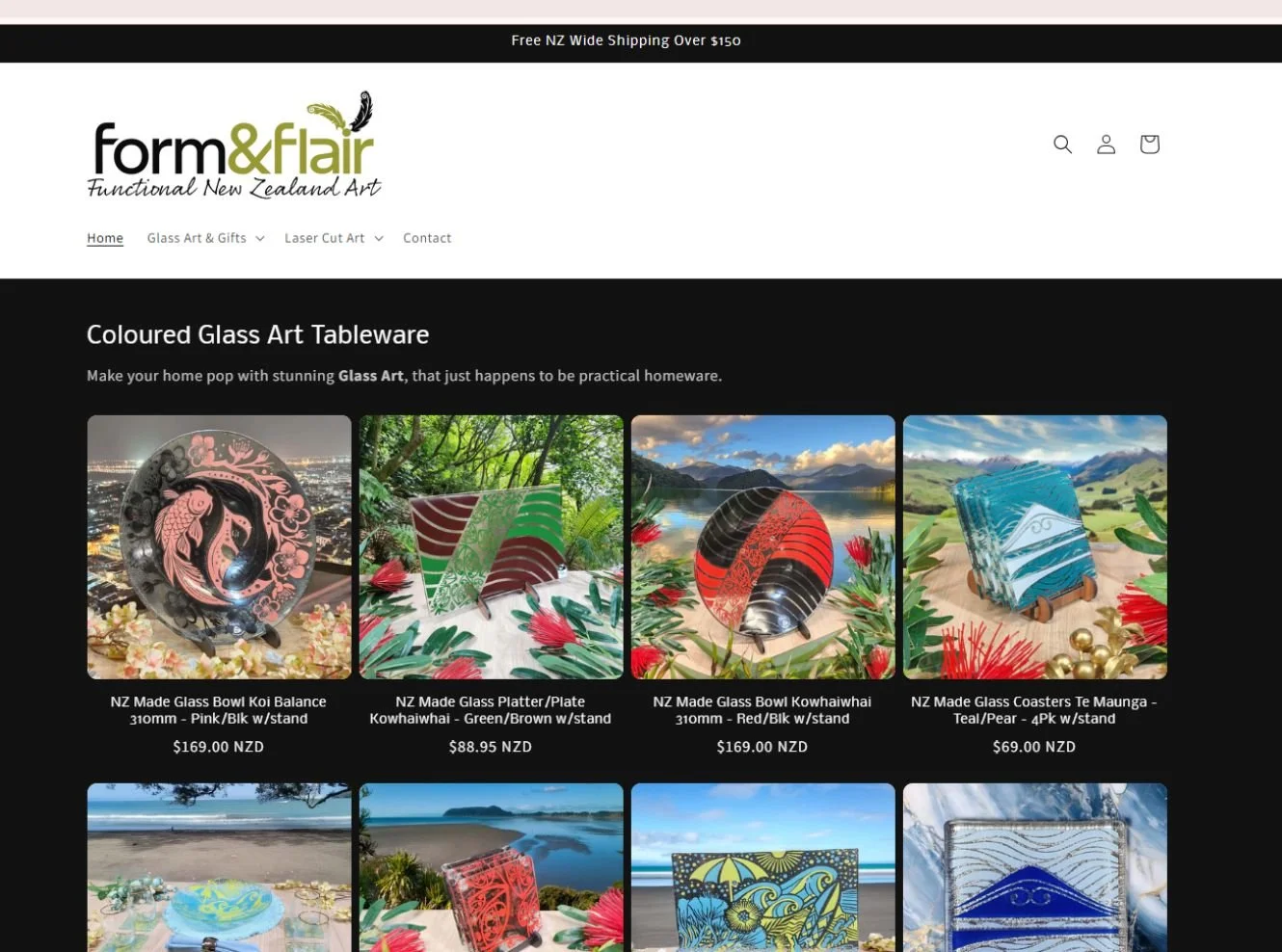

Built two distinct e-commerce websites from scratch: fiery.co.nz (B2B wholesale) and formandflair.co.nz (B2C retail).

Executed a full digital strategy, including Google Ads, Analytics, and Google Shopping integration.

Achieved high Google search rankings for key products.

Set up AI-driven social media feeds synced to the websites.

Business Development:

Designed and built stunning trade show display stands, which became the primary source of new B2B clients.

Used trade shows to gather direct market feedback, fostering relationships and co-developing new ranges to meet changing market requirements.

Conducted market research by visiting major gift/souvenir trade fairs in Australia and visiting local gift shops to discuss their needs and market trends.

Successful Exit

After completely transforming the business, I packaged the streamlined operation and sold it for 5x the initial purchase price. I provided a comprehensive two-week handover to the new owners, who were able to pick up the new, simplified production process quickly.