2011 - 2016

Auckland, New Zealand

Case Study: Lynchbuilt Engineering - Race Car Fabrication

The Role: Performance Engineering Specialist

As a specialist contractor at Lynchbuilt Engineering, I worked with a close friend in a high-performance workshop environment. The business specialised in building and modifying classic race cars and "resto-mods"—classic vehicles updated with modern engines, drivelines, suspension, and electronics.

My role was multi-disciplinary, covering the entire project lifecycle from initial design and fabrication through to final tuning, track setup, and driver support.

Core Expertise & Services Delivered

Engine, Drivetrain & Electronics

Engine Swaps & Repowers: Specialised in fitting late-model, high-performance engines into classic cars for both road and race applications. Examples include:

Nissan: SR20, RB25/RB26 Turbo, VH45 V8, VQ35 V6

Honda: B16, F20C

Toyota: 4AGE, 1UZ-FE

Vauxhall: C20XE

Chevrolet: LS V8

Race Engine Building: Assembled and blueprinted high-performance engines, managing all aspects of the build:

Rotating Assembly: Custom crank machining (knife-edging, cross-drilling, balancing), and fitting forged pistons and conrods.

Cylinder Heads: Performed cylinder head porting and fitting of oversized valves.

Valvetrain: Specified and built custom valve trains, including custom camshafts, cam timing, adjustable gears, pushrods, rocker assemblies, and shims.

Oiling Systems: Engineered advanced oiling solutions, from boring oil galleries and installing larger pumps to fabricating full dry-sump systems, custom gated sumps, and oil pickups.

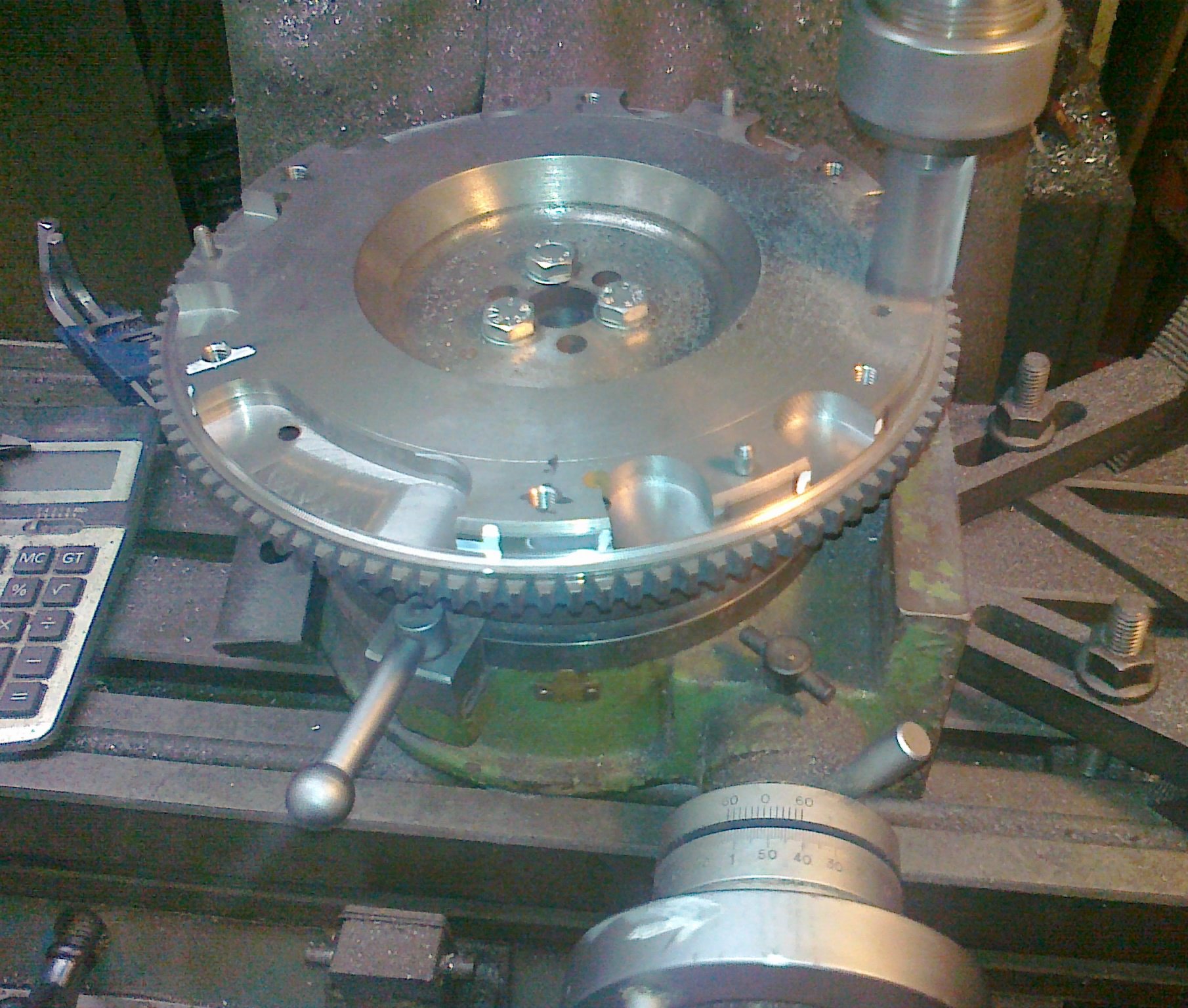

Clutch & Flywheel: Machined custom flywheels and fitted clutch assemblies.

ECU & Tuning: Managed full wiring harness design, fabrication, and installation for standalone ECUs and for modernising older vehicles, many of which had unsafe original wiring. This included creating custom ignition systems (trigger wheels, performance coils, ignition leads) and integrating additional sensors and accessory controls.

Dyno & Road Tuning: Took client vehicles to the dyno for tuning sessions, performing detailed carburettor tuning and assisting with standalone ECU mapping to extract maximum safe performance. This was supplemented with on-road and track tuning.

Drivetrain: Executed full driveline conversions (including manual swaps), specializing in HD Toyota 5spd gearboxes onto various engine makes and vehicles, fabricated custom bellhousing adapters and flywheels for these conversions, built and upgraded transmissions (including straight cut gear conversions), and fitted upgraded and multi-plate race clutches with custom hydraulic systems.

Axles & Differentials: Installed and tuned limited-slip differentials (LSDs), including performing complete Hilux LSD rear axle conversions into various vehicles and tuning diff/gear ratios.

Performance Systems: Fabricated full custom exhaust systems, including headers and turbo manifolds. Engineered complete cooling solutions, including oil coolers, electric water pumps, and radiator upgrades.

Fabrication & Machining

Custom Solutions: Because many projects involved fitting modern engines and drivelines into older classic cars, a large number of parts had to be custom fabricated from scratch, often as one-off items.

Advanced Fabrication: Utilised a comprehensive range of equipment for this custom work, including MIG, TIG, and gas welding, lathe and mill operation, and mandrel tube bending.

Chassis & Body: Fabricated and installed roll cages, performed custom body modifications, and fabricated metal panels.

General Fabrication: Built and modified trailers and other general engineering projects. From boat work to tractors & farm equipment, trucks, coffee van and mobile food vans, shop fitouts and much more.

Race Driving, Performance & Setup

Suspension & Brakes: Designed and fabricated custom suspension systems, performed full vehicle setups including corner weighting, and engineered brake upgrades.

Race Driving & Trackside Support: Actively raced our own team cars in circuit racing, tarmac rallies, sealed bent sprints, and club days. In parallel, provided comprehensive on-track pit crewing for both our team and for clients. Services included:

Full pre-race spanner checks and safety inspections.

In-pit suspension and setup adjustments.

Tyre pressure and temperature monitoring.

Fuel loading to calculate minimum weight for race distance.

ECU data analysis between sessions.

Live tuning based on conditions and driver feedback.

Driver Coaching & Vehicle Assessment: Offered on-track driver training to help clients maximise their vehicle's performance. This extended to driving clients' vehicles at track days to assess their handling, identify setup issues, and demonstrate the car's full capabilities.

Event Promotion & Technical Consultation

Event Management: Managed the company's presence at major trade shows and motorsport events. This included designing, fabricating, and setting up all display stands and signage.

Client Engagement: Acted as the primary technical expert on-site, showcasing company vehicles and client cars. I engaged with potential clients, walking them through the technical details of our work and advising them on potential builds for their own vehicles.

Industry Collaboration & Networking: Actively worked with a wide network of other industry experts to deliver comprehensive solutions. This included collaborating with engine machine shops, camshaft grinders, flow testing companies, dyno tuners, body shops, carburettor specialists, hot rod builders, track management companies, clubs, and race event organisers.